Supply Chain definition: Supply Chain is a connected system of organizations, people, activities, information, and resources designed to procure raw materials, convert them to finished products, and deliver the finished product to the end consumer. Supply Chain involves all the activities and processes of transforming natural resources, raw materials, and components into a finished commercial product delivered to the end customer.

Supply Chain covers the entire gamut of an Organization and even extends to entities outside the Organization, including vendors and customers. Every activity that helps deliver the product or services to the customers is a part of the Supply Chain. Supply Chain is ubiquitous and covers all the operational departments of an organization, including Purchasing, Stores, Warehouses, Manufacturing, Order Processing, and Dispatch. Some of the processes covered by the chain are:

Supply Chain Management (SCM) definition: It coordinates the activities related to the smooth flow of materials and services across the supply chain to ensure on-time delivery of products and services to the customers.

As per the Supply Chain Operational Reference (SCOR) model developed by Supply Chain Council (SCC), Supply Chain Management focuses on five areas: plan, source, make, deliver, and return.

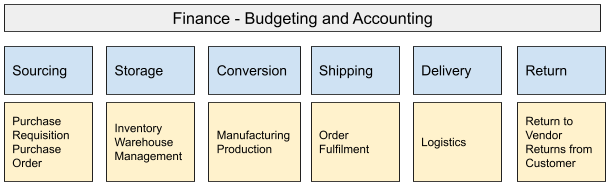

Supply Chain Management focuses on the following business processes as shown in the diagram.

Supply Chain Management Software helps to execute the supply chain processes discussed above. Customers can use disparate software to handle different business process areas based on their unique requirements. For example, they could use a Procurement System to manage their procurement processes and a Transportation Management System to handle their logistics processes.

The challenge with using disparate systems is that they tend to work as Silos, and integrating them and maintaining the integration could be a complicated task. One way to handle the challenge of silo application is to procure an integrated Supply Chain Management Software. These applications could be industry-specific and come with their inbuilt integration that helps incorporate the Supply Chain Management processes.

A good Supply Chain Management Software should support forecasting, demand planning, and materials planning. Besides, it should support the unique processes and features relating to your industry.

One of SCM Software’s challenges is that it does not integrate with the other business areas like Finance and HRMS. Organizations can accomplish this integration by using Supply Chain Management ERP.

Supply Chain Management ERP is a Supply Chain Management Software that integrates Supply chain management (SCM) Activities to the other business areas including Financials and HRMS. This provides the management with an integrated view of the Organization’s performance. Since Supply Chain Management ERP can provide the real-time financial impact of the Supply Chain Transactions, they enable early identification of unprofitable transactions.

| No | Feature | Module | Industry | (M/O) |

| 1 | Create vendors | Purchasing | All | M |

| 2 | Create purchase requisitions | Purchasing | All | O |

| 3 | Approve purchase requisitions | Purchasing | All | O |

| 4 | Create purchase orders (PO) | Purchasing | All | M |

| 5 | Approve PO | Purchasing | All | M |

| 6 | Create purchase agreements | Purchasing | All | O |

| 7 | Track PO amendments | Purchasing | All | M |

| 8 | Close PO | Purchasing | All | M |

| 9 | Budgetary tracking | Purchasing | All | O |

| 10 | Receive material against PO | Inventory | Many | M |

| 11 | Return material to vendor | Inventory | Many | M |

| 12 | Issue materials to sales | Inventory | Many | M |

| 13 | Process material returns from customers | Inventory | Many | M |

| 14 | Inventory adjustments | Inventory | Many | M |

| 15 | Material transfers | Inventory | Many | O |

| 16 | Process physical inventory adjustments | Inventory | Many | O |

| 17 | Record ASN (Advance Shipment Notice) | Inventory | Many | O |

| 18 | Support costing method as applicable | Costing | Many | M |

| 19 | Create quotes to be send to customer | Order Management | All | O |

| 20 | Record sales order | Order Management | All | M |

| 21 | Pick materials from warehouse | Order Management | Many | M |

| 22 | Material Packing and Dispatch | Order Management | Many | M |

| 23 | Process material returns from customers | Order Management | Many | M |

| 24 | Direct shipment | Order Management | Distribution | O |

| 25 | Consignment sales | Order Management | Retail | O |

| 26 | Internal orders | Order Management | All | O |

| 27 | Create and process production orders | Manufacturing | Manufacturing | M |

| 28 | Configure Bill of Materials | Manufacturing | Manufacturing | M |

| 29 | Integration with financial applications like receivables and payables | All | All | O |

| 30 | Create accounting entries and transfer to GL | All | All | M |

Demand Planning Software handles the recording of forecasted demand and processing the forecast to plan for the availability of raw materials and production capacity to produce the finished product to meet the forecast demand. The module processes three planning types, including Materials Requirements Planning (MRP), Min-Max planning, and Reorder Point Planning.

Warehouse Management Software: This module augments the inventory management module and specializes in advanced storage, tracking, and processing of the material movements in the warehouses. This module enhances the accuracy of the receiving and picking process. Warehouse management uses technologies like barcodes and RFID to ensure inventory optimization.

The Transportation Management Software augments the dispatch process by providing a complete track of the finished product as it moves from the Factory Gates until it reaches the Customer’s gates. This tracking ensures in-transit material quality and helps the smooth transfer of ownership of the material to the Customer. This module uses advanced technologies like IoT (Internet of Things) and GPS to ensure quality and reduce delays.

Each industry group and industry has its own unique needs from Supply Chain. For example, direct shipment, where the supplier ships the material directly to the customer, is a feature of the distribution industry. Consignment sales, where the material is stored in the customer warehouse, is a retail industry feature. Complexities of the Supply Chain are different for each industry. The ERP Application must meet the industry supply chain requirements.

The supply chains of two companies in the same industry could be different. Since the chain provides unique competitive advantages to the company, it must identify such critical requirements and ensure that the selected ERP satisfies the company-specific needs.

Supply chain complexity increases exponentially with business growth. So any ERP for Supply Chain should be able to handle this complexity as the company grows.

People are technology savvy: ERP systems that handle the supply chain are complex. It needs users to be educated and technology savvy. Users should not only learn the application but also learn how to get support to resolve the issues.

Change management: ERP systems for supply chains entail process changes. A thorough change management process is required before and during ERP implementation. Since change management is inevitable, companies should select ERP systems that require the least amount of change management effort.

Availability of quick and quality support: Uninterrupted supply chain is an essential requirement of any company. Hence ERP Vendors should ensure prompt and quality support to resolve any issues relating to the supply chain.

Supply Chain Management ERP Software supports both push and pull-based planning. By enabling accurate forecasts, the planning outputs become more accurate. It leads to improved process efficiency.

Supply chain ERP systems ensure clear visibility for management along the entire chain. It helps quickly identify bottlenecks and inefficiencies

ERP systems provide data, used benchmarking, and continuous improvement within the Organization.

Improvement in process efficiencies, increased inventory turnover, and asset utilization will lower the cost per unit of the finished product driving up the profitability per unit.

Accurate planning ensures regular stocking and replenishment of items. It increases the inventory turnover.

Accurate capacity planning that ERP systems enable will lead to better utilization of machines and labor.

An ERP for Supply Chain Management helps companies assure the firm promised date and deliver on (or before) the promised date. ERP helps provide relevant information to the Customer promptly. The clarity in communication and promptness in delivering products and services leads to increased customer satisfaction and repeat & referral orders.

In an On-Premise ERP, the Customer manages ERP Software and the technology infrastructure (Hardware). This level of control enables the Customer to customize the software to suit their unique supply chain processes. This flexibility comes at the cost of managing the unfamiliar IT infrastructure terrain.

In a Cloud ERP, the ERP Vendor manages Cloud-based ERP, both software and hardware. The Customer can configure the ERP Software to meet their business requirements. There is limited flexibility in customizing the application to meet the unique business processes. In some cases, the Customer will need to modify their business processes to suit the operations supported by ERP.

The main benefits of Cloud ERP are reduction in cost and complexity of managing the IT Infrastructure. Irrespective of Cloud or On-premise ERP, the key is to understand the critical business requirements and ensure that the ERP system that you choose can quickly meet those requirements.

New technology will upend the way Organizations are managing their Supply Chain. Technologies like Blockchain, Industrial Internet of Things (IIoT), and Robotic Process Automation (RPA) will fundamentally alter the way businesses operate and will have a profound impact on the Supply Chains of the Future.

ERP for Supply Chain as a foundation to build a platform for future technologies. It means that ERP for Supply Chain is no longer a luxury but a necessity for an Organization to transform the Supply Chain of the future.

Gartner has coined the term ‘Postmodern ERP’ to describe how advanced technologies like Artificial Intelligence (AI), Machine Learning (ML), and other technologies will impact ERP of the future.

FAQ: Supply Chain Management ERP and Procurement

FAQ: Supply Chain Management ERP and Procurement

ERP for purchasing automates the procurement process to ensure better data visualization, analysis, and reporting. The purchasing ERP eliminates miscommunication, inaccurate data, and poor decision-making as a centralized data source. With one data set to depend on, each procurement worker has access to a whole, centralized data source. A procurement ERP system can provide the following advantages:

Procurement entails simple and complex purchase deals. Also, a company can procure goods only once or repeatedly. Purchasing ERP is the best system for managing the procurement process. In an Supply Chain Management ERP, procurement appears as a module with different features.

A company can get this module to track quote requests and related purchase orders, invoices, accounts payables, sales orders, shipments, etc. The procurement ERP module should offer the features we listed above.

An ERP procurement tool can be a cloud or an on-premise solution. A cloud ERP system stays on internet-based servers. Usually, the software provider manages these servers on behalf of customers. Hence, they tackle software upgrading and maintenance fees.

They also manage server downtimes on the customer’s behalf, making the cloud ERP solution the cheapest solution. Although its data security does not match that of on-premise ERP, it allows accessibility from anywhere.

Every business runs a unique procurement process and encounters some challenges. Procurement challenges that most companies face include the following:

Organizations thrive by facilitating procurement and other processes. Procurement of goods or services is a process with a life cycle. The procurement life cycle includes all steps for getting goods or services.

It should help a company obtain goods without delay to reduce operation costs. A procurement life cycle improves customer relationships. It ensures that the organization receives supplies for producing products for customers without delay. A procurement life cycle provides the following steps: